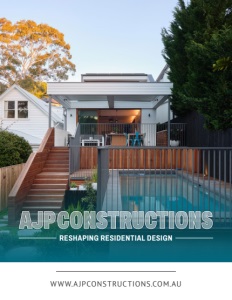

Reshaping Residential Design

Timber Innovation leads to top design builds

AJP Constructions has quietly built a reputation as one of Sydney’s most forward-thinking residential builders, combining technical precision, architectural excellence, and a commitment to sustainable materials. Under the leadership of Founder and Director Andrew Payton, the boutique firm has carved out a distinct niche in high-end residential construction, with a particular expertise in cross-laminated timber (CLT) and detail-driven project delivery.

Founded in 2011 and based in New South Wales, AJP has become a trusted name among architects and homeowners alike, renowned for undertaking complex, design-led builds that require exceptional craftsmanship and innovative approaches.

Niche market leader

“I started the company in 2011 as a bit of a one-man band,” says Payton. “We grew from there, but it was always a sustained effort.”

Like many builders, AJP began with smaller projects before steadily gaining traction and taking on more complex work. But unlike many, Payton wasn’t content to grow in size—he focused on growing in focus. After early expansion, including hiring a team and managing multiple projects at once, Payton made an important decision in 2017-2018 that would steer the company in a new, more intentional direction.

“We brought a coach on board and started working on our marketing and internal systems. That’s when we began zoning in on our niche and decided to be very clear about the kind of work we wanted to take on,” Payton explains. “That was probably where we saw the most controlled growth in the shortest amount of time.”

Quality over quantity, by design

Today, AJP Constructions is recognized for producing high-end architectural homes that emphasize clean finishes, intricate details, and the highest level of craftsmanship. The company typically manages three to four projects at a time, enabling it to fully commit to the exacting standards its clients—and architects—expect.

“Our work is mainly new builds or large-scale renovations with a lot of detail,” says Payton. “We’re talking about knockdown-rebuilds with minimal clearances, flush finishes, and refined architectural elements. Every millimetre counts.”

This disciplined approach to execution sets AJP apart. Rather than scaling for volume, Payton has chosen to keep the team small and elite, typically comprising between 13 and 15 employees, while bringing in trusted subcontractors as needed for specific tasks, such as cladding and carpentry.

“We’ve had opportunities to grow more, but we’re not interested in chasing volume,” Payton says. “We’d rather have a manageable workload and do each project well.”

Craftsmanship on display

When asked about a standout project that reflects AJP’s attention to detail and signature style, Payton points to a recently completed home in North Bondi—a striking three-storey build created in collaboration with Mather Bear Architects.

“It was a full CLT build, and we’re really proud of it,” Payton says. “The finishes were extremely tricky—flush reveals, tight tolerances, not a lot of room for error. But the result speaks for itself.”

Projects like this illustrate the unique value AJP brings to the table: blending deep respect for architectural intent with construction techniques that elevate both form and function.

Cross-laminated timber in residential builds

One of the most critical innovations AJP has championed is cross-laminated timber (CLT). This prefabricated, solid-wood panel system has been widely used in commercial buildings but is only recently gaining traction in residential construction.

“We started using CLT in 2017, and since then we’ve done numerous builds with it,” Payton explains. “It’s our specialty now.”

CLT panels are engineered off-site and arrive ready to assemble, significantly reducing build time while improving precision and minimizing waste. This technology aligns with AJP’s values, both in terms of quality and sustainability.

“There’s far less on-site labour required, and because everything is prefabricated, there’s a lot less waste,” Payton says. “Plus, CLT is carbon negative—it stores more carbon than it emits in its production and installation. That’s a big win for sustainability.”

Digital tools for smarter construction

Alongside CLT, AJP Constructions has invested in advanced construction technology to maintain quality and mitigate risk. Specifically, the use of Building Information Modeling (BIM) has become a critical component of their process.

“When we did our first CLT project, it was very analog,” Payton recalls. “We were measuring on-site, and there was a lot of room for error. Now, we use BIM to model the whole build and detect clashes between building components before anything goes to manufacturing.”

The result is a streamlined process that saves time, reduces rework, and ensures that every element of the structure, from the smallest detail to the largest, is fully coordinated.

AJP also incorporates 3D laser scanning and point cloud modeling for renovation projects. “When you’re trying to integrate a prefab structure with an old building, the existing conditions have to be mapped exactly,” Payton explains. “That’s where this technology helps.”

The strength of a collaborative team

While technology plays a key role in AJP’s process, Payton emphasizes that none of it matters without the right people. The team is small, close-knit, and united by a shared commitment to craftsmanship.

“We want people who are in it for the long haul,” Payton says. “People who share the vision, understand the quality we expect, and want to grow with us.”

Even when team members eventually branch off to start their own businesses—a natural outcome for ambitious tradespeople—Payton sees it as a positive reflection of the culture he’s built. “We support them in that. The goal is to create an environment where people learn, develop, and then pass that experience on, whether that’s with us or elsewhere.”

This same philosophy extends to subcontractors and suppliers. AJP maintains long-term relationships with key partners to ensure consistency and trust across all projects.

“Everyone we work with—architects, engineers, subcontractors—we try to keep working with the same people. They get to know our standards, and we know how they operate. That continuity reduces friction on-site.”

Early engagement for a competitive advantage

Another key to AJP’s success is its approach to project engagement. Unlike many builders who come into the process after designs are finalized, AJP prefers to be involved from the earliest stages.

“Most of our projects are done through early contractor involvement,” says Payton. “That means the client brings us in alongside the architect and engineer from the beginning, so we can help shape the project from a buildability standpoint.”

This upfront collaboration saves time and money, especially in today’s volatile economic environment.

“Prices have gone through the roof in recent years. If you design a home without understanding the build costs, you might end up with something you can’t afford,” Payton explains. “With early involvement, we can run real-time costing and catch issues early, so you don’t have to redesign later or resubmit to the council. It’s just a smarter way to build.”

Sustainability as a guiding principle

Sustainability is a core value at AJP Constructions, extending beyond the use of Cross-Laminated Timber (CLT). The team continually seeks ways to reduce its environmental impact through informed material choices, effective waste management, and intelligent design.

“There are so many different directions you can take when it comes to sustainability,” says Payton. “We’re always learning, always evolving. But CLT has been a big step in the right direction for us. It drastically reduces waste and offers a healthier indoor environment.”

The company also prioritizes durability and longevity in its builds, thereby minimizing the need for future renovations or repairs and contributing to a longer lifecycle for the homes it creates.

Award-winning work and industry recognition

Over the years, AJP’s commitment to excellence has been recognized by industry bodies across the country. The company submits to the Master Builders Association of New South Wales (MBA NSW) awards annually and has received multiple accolades.

“We’ve been very fortunate to be successful in quite a few entries,” says Payton. “But it’s more than just a trophy—it gives the team something to strive for. When our team knows the judges are going to walk through the project, they push themselves even harder to make sure every finish is perfect.”

AJP’s awards include wins in categories such as Housing Alterations/Additions, and Payton himself was named MBA’s National Young Builder of the Year—a significant endorsement of his leadership in the next generation of Australian construction.

Expanding vision, sustaining quality

With 2025 underway, AJP Construction is focused on deepening its expertise and expanding its impact, all while maintaining its commitment to quality.

“We’re just scratching the surface of what’s possible with CLT and BIM,” Payton says. “There’s still so much room to improve how we’re utilizing these systems—to make builds faster, more efficient, and more sustainable.”

Beyond project execution, the company is also exploring the possibility of becoming more involved in property development, creating beautifully designed, sustainably built homes under its own banner.

“We’d love to take the lead on some developments ourselves,” Payton reveals. “It would be an opportunity to showcase what’s possible when design, sustainability, and craftsmanship all come together.”

At a Glance

Who: AJP Constructions

What: A Sydney-based residential building company specialising in high-end architectural homes and sustainable construction methods, particularly using cross-laminated timber (CLT).

Where: Sydney, Australia

Website: www.ajpconstructions.com.au

PREFERRED VENDORS/PARTNERS

Shamrock Joinery – www.shamrockjoinery.com.au

Shamrock Joinery is redefining Australian craftsmanship with high-performance timber windows and doors. From heritage to contemporary designs, our award-winning Eco Logic® range delivers superior thermal performance using premium materials. Proudly Australian-made, we’re committed to innovation, sustainability, and protecting local manufacturing while setting a new benchmark for quality in the built environment.

This information will never be shared to third parties

This information will never be shared to third parties