Australian Construction Products (ACP)

Investing in Safety

Business View Oceania interviews representatives of Australian Construction Products (ACP) for our focus on Manufacturing in the Construction Sector

The importance of road safety cannot be overstated. During the 12 months ending January 2022, there were 1,134 road deaths in Australia – a 2.3% increase compared with the same period 12 months earlier. Guardrails are one of the most important safety systems currently employed to help reduce this number, preventing vehicles from colliding with objects behind the rail, and controlling the trajectory of the vehicle should a collision prove unavoidable.

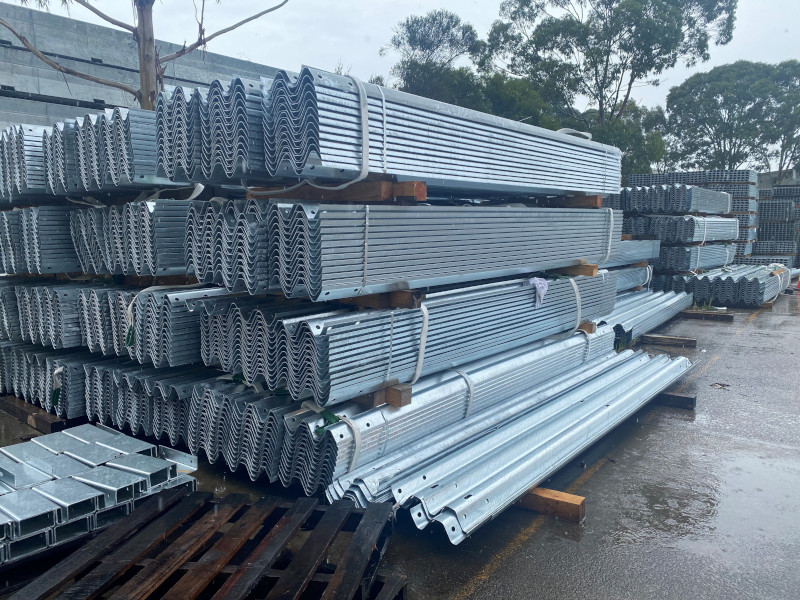

Australian Construction Products (ACP) is one of Australia’s leading manufacturers and suppliers of guardrail and roadside safety products, having been in operation since 2000. The company offers a full suite of innovative solutions in line with the latest crash-test requirements. Part of the Jaybro Group since September 2021, ACP now forms the largest civil infrastructure supply company in the country.

“ACP has grown significantly in the two decades or so that have passed since its founding,” says Wesam Refahi, the company’s Product Manager. “We’ve built up a very robust road safety barrier product range serving both the temporary and permanent barrier markets. As well as our own proprietary products, we’ve also been involved in research and development with other companies – both in Australia and overseas.”

ACP is continuously working to come up with better and safer products, with regulatory shifts often guiding this process. One such shift came in 2015 when the Australian and New Zealand Standard for Safety Barriers and Associated Devices was developed to incorporate the Manual for Assessing Safety Hardware (MASH) standard.

General Manager, Zalman Paris, shares, “It’s a real privilege running a business like ACP, as we are at the forefront of making roads and the general built infrastructure environment safer. For the team that have worked or are working at ACP over the last few years, we have had the fortunate luck to herald a new standard into place, that being MASH 2016. This new Standard was adopted in Australia and New Zealand around the end of 2018 and there has been a progressive roll out of new barriers over the last four years with various sunset clauses on old standard products coming to an end and the new ones commencing from a design and construct perspective .”

General Manager, Zalman Paris, shares, “It’s a real privilege running a business like ACP, as we are at the forefront of making roads and the general built infrastructure environment safer. For the team that have worked or are working at ACP over the last few years, we have had the fortunate luck to herald a new standard into place, that being MASH 2016. This new Standard was adopted in Australia and New Zealand around the end of 2018 and there has been a progressive roll out of new barriers over the last four years with various sunset clauses on old standard products coming to an end and the new ones commencing from a design and construct perspective .”

Paris indicates that this has been a real disrupt to the industry and it has seen these new tested items come in and replace the old and, in some cases, non tested items. Ultimately resulting in a lower cost and safer roads. He notes, “We talk about the triple bottom line and in this case the MASH standard has made the roads safer for the community. It has generally come at a lower cost to the asset owners or they have got more barrier for their money and its simplified the manufacturing process in many cases for ACP. Its been a Win Win Win for all concerned.”

From 2018 onwards, road authorities around Australia started to mandate and adopt MASH-tested products. Refahi explains, “That forced the market to retest or upgrade its product range to meet the new standards of testing. This has led to significant safety improvements, particularly as vehicles have become a lot heavier and larger than they were when the previous standards were created. The new MASH testing has instigated a raft of new product development as part of an ongoing process.”

This ongoing process is aided by the deployment of the latest technology whenever ACP is pursuing the development of new products. “More of our internal systems are immersed in online platforms, through ERP and CRM systems,” adds Will Truong, state Sales Manager for Queensland and the Northern Territory. “Our support and supply chain teams are more efficient in performing functions and retrieving data – we’re able to adopt an almost just-in-time process to keep our stock lean and maintain our customer service. Our sales teams are more market-aware when facing customers, and have more meaningful conversations on the back of real, live information.”

However, despite ACP’s commitment to cutting-edge technology, that hasn’t prevented the company from experiencing challenges – particularly over the last two years. As with any company, the impact of the COVID-19 pandemic has been unavoidable. “Supply has been the number one challenge for us over the last couple of years,” Refahi reports. “There’s also been material shortages, container shortages, and freight challenges. In terms of supply, raw materials have taken the biggest hit, not just for our own products, but also those that are made and imported from overseas that we then supply in Australia. That’s delayed our supply chain and the delivery of material to customers.”

Meeting these challenges – whether related to COVID or not – has been made easier by the support of ACP’s extensive partner network. “In terms of our U.S. product range, for example, we have had a long relationship with Lindsay Transportation Solutions, with whom we’ve been collaborating for a number of years now. We’ve also done a lot of product testing with Holmes Solutions in New Zealand. They are another company that we’ve worked with quite closely to test our products,” Refahi adds.

However, collaboration only represents one of ACP’s core values. Another of the company’s major strengths concerns anticipating market needs and increasing the standards of its products to ensure they are constantly being met. The company is also extremely proud to make Australian products. “The majority of our guardrail products are made in Australia and made from Australian BlueScope steel,” Refahi says.” And the products that we license from the U.S. are, ofcourse, approved here in Australia too.”

In addition, given the products that ACP manufactures, it should come as no surprise that health and safety is also a core concern. As is sustainability. ACP recycles as much scrap material as possible, all its office lighting has been upgraded to LEDs, and the company is using plastic PET strapping in all its warehouses. These values, whether they concern safety or sustainability, represent a major part of ACP’s corporate culture.

“We have a small team of 30 staff nationally, and project a lean and agile, small-business feel,” Truong notes. “Yet, being a part of the Jaybro Group, we enjoy the benefits of a large corporate profile with the structures and policies that go with it. And with Jaybro being voted one of 2021 Australia’s Best Workplaces, it feels like we enjoy the best aspects of a small business culture, with the backing and support of a large corporate juggernaut behind us.”

Although now part of the Jaybro Group, as Truong says, that doesn’t mean ACP can be disregarded as just another company. It works hard to differentiate itself from the competition by prioritizing customer service. “We are not the biggest player in the market – possibly the second – but we are strong in terms of customer service in that we obviously like to meet customer demands whenever we can,” Refahi acknowledges.

In fact, ACP has a strong appreciation of consultation generally, whether it’s with the company’s customers or other industry stakeholders. ACP is keen to work with local governments, designers, and other companies, where it is relevant to do so. These consultations often lead to new product development, which necessarily requires additional investment – something that ACP is more than happy to supply.

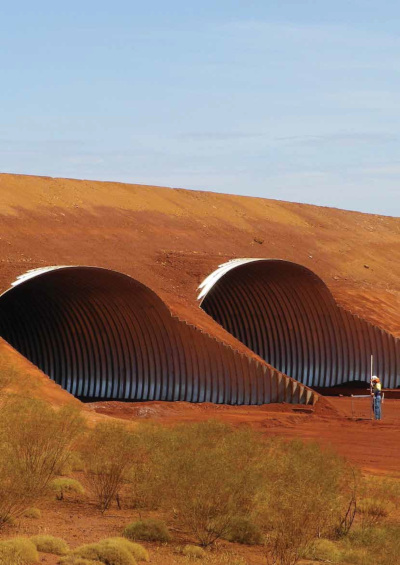

“We’re investing in more capability to expand our engineering design capabilities, to come up with more variations from the standard guardrail design,” Truong continues. “This is in line with the stricter MASH crash-test requirements, but also helps address the more complex project parameters that road authorities face in designing these new roads, including small shoulder and verge widths, more traffic with larger vehicles, more service lines and culverts. We’re trying to come up with more solutions to make life easier for the road authorities and their appointed engineers.”

This investment is, at least in part, driven by an understanding that road safety standards are constantly evolving. Over the next five years, ACP aims to be the number one choice for all things guardrail. The company is committed to adding to its range of innovative engineering solutions on the back of the capital investment that it’s making today. “From a company perspective, it’s important we achieve that return on invested capital to ensure future innovation,” Truong says. “We’ll continue to invest in our people, promoting training and development, providing robust incentives and succession plans, and boosting employee engagement. We want to continue to be a great place to work!”

ACP’s ongoing investment is not only designed to create additional internal benefits, however. Working within road safety, the company understands the importance of its products and the safety standards that they meet. Looking ahead to the future, the company will continue to explore the latest technologies and cutting-edge R&D processes in order to create new products and improve existing ones. “When we help manufacture or license a product that performs better and more safely on the roads, that’s just a win-win for everyone,” Refahi says.

AT A GLANCE

Australian Construction Products (ACP)

What: A leading manufacturer and distributor of steel and civil roading barriers

Where: Sydney, New South Wales

Website: http://www.acprod.com.au/

PREFERRED VENDORS

Bridon-Bekaert: The Ropes Group – www.Bridon-Bekaert.com

We offer BlueStrand barrier rope which is manufactured from 100% Australian made materials and we also offer QRope barrier rope that we manufacture from a combination of Australian and imported components.

Sustainability Initiative:

Bridon-Bekaert has implemented a system to support the collection and reuse of empty reels.

This initiative is aimed at reducing the use of timber and improving the sustainability of the life-saving flexible barrier rope system. Please see details on the tags on our reels.

This information will never be shared to third parties

This information will never be shared to third parties