Summit Building Wash Technologies

Building Wash Robotics

Business View Oceania interviews Ray Tomlinson and Sam Clayton of Summit Building Wash Technologies for our focus on Facilities Management.

One of the most advanced technological innovations currently available in the New Zealand exterior building wash market, the Summit Building Wash Machine, designed and engineered by Summit Building Wash Technologies (Summit BWT), allows for a more efficient, superior detailed building wash that cleans up to three times faster than manual abseiling, runs at a much lower cost, and provides a sustainable alternative to manual building cleaning. Summit Building Wash Technologies, run by founder Ray Tomlinson and engineer Sam Clayton, has been in independent operation for just over two years, and has been in the works under the guide of sister company JT Group for half a decade. In that time, they have managed to design, develop, manufacture, and test their Summit Building Wash Machine, which has produced exceptional results via their test site, Wellington Airport, in Wellington, New Zealand.

Mr. Tomlinson shares his excitement surrounding the introduction of the Summit Building Wash Machine to the retail market, which is set to happen in January of 2022. “About five years ago, as part of my own work in the exterior building wash industry under JT Group, we brought in some overseas technology in hopes of boosting productivity on the job. Abseiling has historically been the most efficient way to wash building exteriors, and when the technology we brought in didn’t surpass that, I decided it was time to create something new that would. There were a number of reasons for this; the main factor was to increase productivity and reduce the cost that comes with those current low rates, because maintaining a crane and having three guys on the job for half a week becomes very expensive.”

Mr. Tomlinson continues, “I also saw a real gap in the market when it comes to quality. For instance, window washing; you traditionally have a worker in a crane basket or abseiling down, washing the windows as they go. Over time the water gets dirtier and dirtier, so the windows at the bottom of the building really aren’t as clean as they should be. Another key issue is that, while the glass is being cleaned, the window seals are not. So that dirty water sits on those seals, and over time it breaks them down. In order to tackle those challenges, we looked at brush technology, which has good applications overseas, but nobody has been able to build or develop a machine that takes that technology and does a better job than traditional abseiling. We have been able to achieve that, and have seen great success through our careful design and application of robotics technology.”

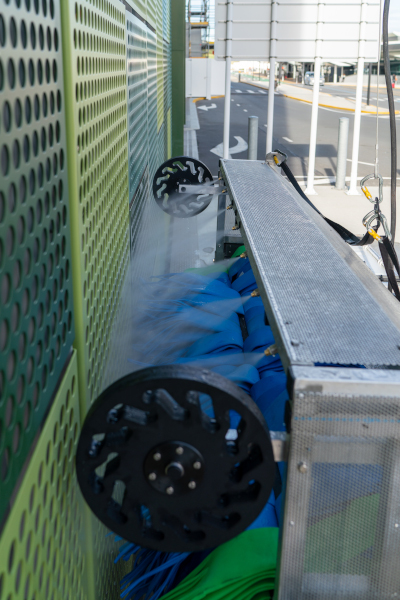

While the Summit Building Wash Machine is not yet released to the public market, examples of its success can be seen via Summit BWT’s key partner, Wellington Airport. Summit BWT have worked with Wellington Airport consistently over the last five years to test their design, and the results have been exceptional. What would usually take three workers three days to complete has been shaved down to a single day of operation using the Summit Building Wash Machine, and the increase of quality and efficiency actually saves building owners money. In addition to reductions in labour and equipment costs, the machine requires only two operators and minimal intervention during run time; presenting a unique opportunity for building owners to save in every area.

While the Summit Building Wash Machine is not yet released to the public market, examples of its success can be seen via Summit BWT’s key partner, Wellington Airport. Summit BWT have worked with Wellington Airport consistently over the last five years to test their design, and the results have been exceptional. What would usually take three workers three days to complete has been shaved down to a single day of operation using the Summit Building Wash Machine, and the increase of quality and efficiency actually saves building owners money. In addition to reductions in labour and equipment costs, the machine requires only two operators and minimal intervention during run time; presenting a unique opportunity for building owners to save in every area.

Summit BWT is currently a two-man operation, though the company is assisted by external contractors where necessary. Alongside Mr. Tomlinson as the company’s founder is mechanical engineer, Sam Clayton. Mr. Clayton also has experience in electrical engineering and has been a vital player in the design and development of the Summit Building Wash Machine. With funding from sister company JT Group, and more recent support from investment group Callaghan Innovations, the machine is well and truly up and running, and is almost ready for market deployment. Mr. Clayton speaks on the market machine itself. “We are in talks with Farra Engineering, a full-service engineering company here in New Zealand, about ways we can improve the machine to make it move around buildings a little easier before we go to market. Given that every building is different in terms of their architecture, we have been presented with some pretty unique challenges. For the moment we plan to service buildings that are a typical, straight up-and-down shape. But in the future, we are excited to develop new mapping and operations technologies that will allow us to clean the exterior of complex structures.”

Summit BWT currently has a patent pending on their adhesion technology, the Façade Adhesion System. Mr. Tomlinson explains, “When we came up with this system, it was tested with the help of Wellington Airport. And for anyone that may have been there or worked there, they will know it’s an incredibly windy environment to be working in; it’s one of the windiest spots in one of the windiest cities in the world. So it has really been the ideal location for us to develop a technology that keeps our machine stuck to the building it’s working on, no matter the environmental conditions.”

Another driver for the creation and implementation of the Summit Building Wash Machine is environmental sustainability. Summit BWT provides an eco-friendly solution that reduces over 85% of water use, and waste, compared to traditional exterior building wash methods, and operates via a fully electrical system fuelled by rechargeable batteries. The machine’s brush technology also eliminates the need for any harsh chemicals, which in turn eliminates any chemical run-off into stormwater drains and water reservoirs that may be located close to client structures.

Mr Tomlinson shares that a significant challenge facing Summit BWT is the hesitancy of building owners to take on such a new technology. “Something we have really worked to overcome, and will need to continue to work towards, is having building owners come on board with us and our technology. The exterior building wash industry has been operated in very much the same few ways for a long time, so implementing this change into the market is no easy feat. A large part of changing the attitudes of building owners is actually bringing to their attention to the fact that their buildings aren’t being washed as they should be. By showing them the success of our machine on the exterior of Wellington Airport and raising awareness about the lack of quality and consistency currently in the market, we hope to permanently change the way these buildings are being cleaned.”

The future of Summit BWT, and the Summit Building Wash Machine, looks bright. AI mapping and reporting technology is currently in the works for future development, with the help of Callaghan innovations and Farra engineering. Summit BWT also aims to continue developing their machine to broaden the scope of their service to architecturally complex structures, and buildings above 20 storeys high. Currently, Summit BWT is taking expressions of interest from building owners and qualified organisations that would like to take the Summit Building Wash Machine on board for the exterior cleaning of their structure, as well as suggestions for additional features that would improve the scope of the machine for their building. For inquiries, contact Mr. Ray Tomlinson via email at ray@summitbwt.co.nz, and be sure to continue watching this space!

AT A GLANCE

Summit Building Wash Technologies

What: Provider of automated exterior building wash technologies throughout New Zealand

Where: Summit Building Wash Technologies is headquartered in Lower Hutt, New Zealand

Website: https://www.summitbwt.com/

PREFERRED VENDORS

Zone Law – www.zonelaw.co.nz

This information will never be shared to third parties

This information will never be shared to third parties