Based on the interview with Brent Clarke

History and Background

Martin Brower was first started in 1956 in Chicago, Illinois, with their initial field of work focusing on distribution. Today, more than 50 years later, their operational capabilities stretch across the entire supply chain model. They are in quite a unique position, with McDonald’s as their key client in almost all of their markets which span nineteen countries. It was largely due to Martin Brower’s operational capabilities, that Mcdonald’s recently received an award for having the second best supply chain in the world.

Brent Clarke is the Strategic Operations Director for the company in Australia and New Zealand. He says the acquisition of Keystone in 2012 has allowed them to truly expand on a global level. There has been a lot of leveraging of best practices globally to ensure operational and functional alignment and efficiency.

Blueprint for efficiency

“One of the things we have been blessed with is our relationship with McDonald’s. McDonald’s has been very successful in their growth and we’ve grown with them to a point where capacity in our system is at a premium and we are now stretched beyond what I call an effective distribution in some parts of the region” Clarke explains.

Keeping it simple goes a long way with logistics and while Martin Brower delivers in excess of 1,000 different SKU’s to over 1,100 restaurants, consistency and communication is critical. Timing means everything in the world of fast food and on time delivery success is achieved by Martin Brower over 98% of the time. Consumer demands mean the orders are consistent with deliveries to restaurants averaging 2-3 per week.

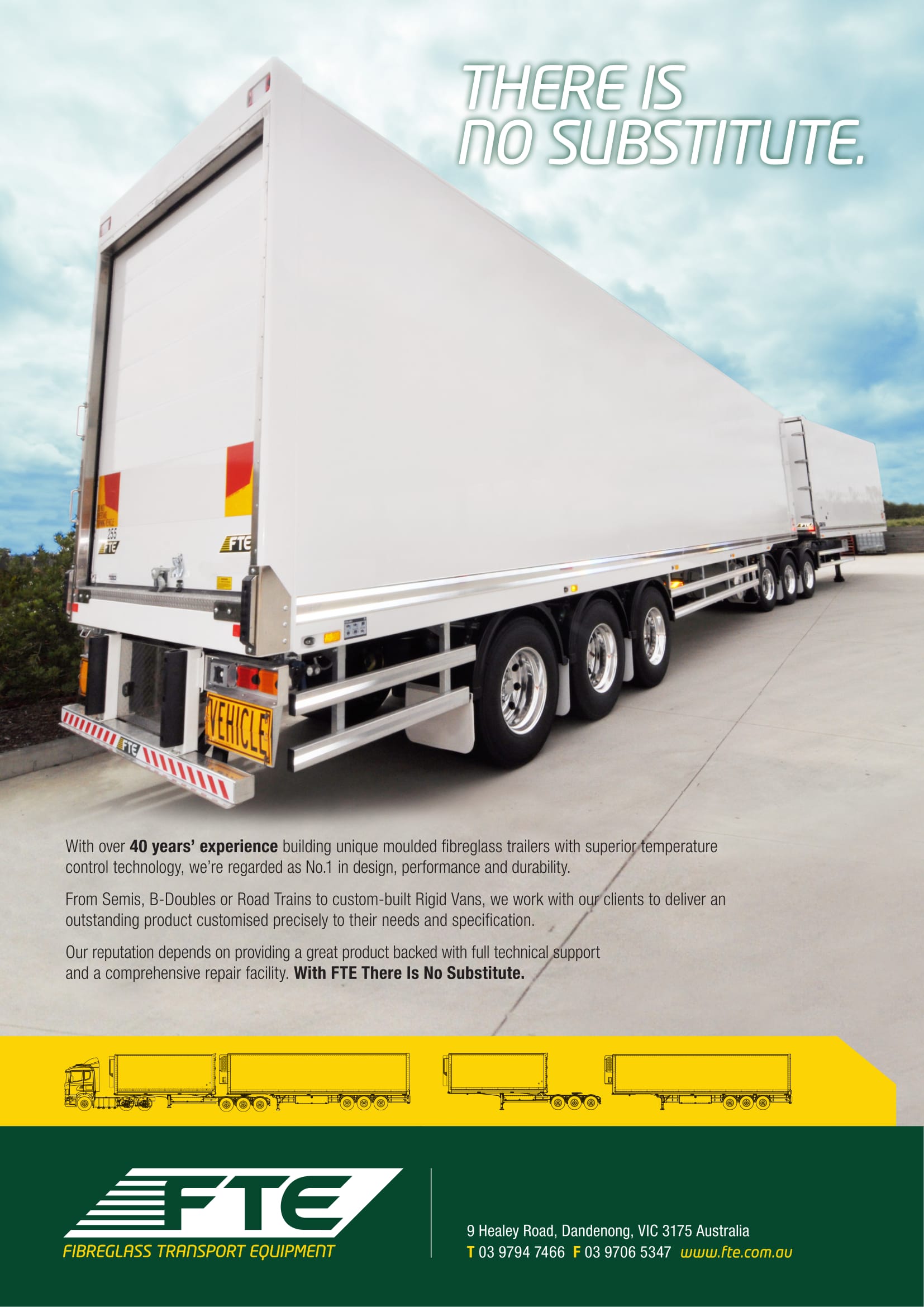

Each delivery vehicle uses Euro Scan technology to monitor the air temperature remotely, ensuring the quality of the product is optimal. Paragon, a routing software package, optimises road routes to make the delivery more direct, as well as reducing the company’s carbon footprint. On-board telematics will also computerise a large part of the delivery process, furthering reducing the impact on the restaurant at delivery time.

Martin Brower distribution centres are not highly automated. Although users of WMS in other regions, they are currently looking into deploying the technology locally.

“We are a high volume, low touch business. What we are trying to do is make sure we have efficient inventory management. Product flows on a regular basis. We’re turning our inventory in all of our facilities once every 7-10 days. For some of product it’s every two days or daily,” says Clarke.

Just as the consumer is used to receiving the same quality Big Mac combo, regardless of their global location, Martin Brower focuses on ensuring that the execution of the delivery process to the restaurant is second to none. They are currently building a new distribution centre in Western Sydney, which will be the largest facility in Australia and will be their flagship facility. It will combine their major corporate offices and two distribution centres into one and Clarke says the expected move in date will be mid-October.

Client Chain Management

Martin Brower wants to be known as the company who provide innovative supply chain solutions. It’s more than logistics, the overall planning, forecasting and managing production with different manufacturers to meet projections is key to their success. As McDonald’s offers many promotions every year, Martin Brower’s role is to support the management of the risks.

Clarke reveals that a lot of the work they do is in collaboration with the different Franchisees. Regular evaluations are done of stock requirements and the individual reverse logistics needs. Field service representatives, specialists in this area, visit the restaurants at least twice a year to assist with education, training and support for inventory and ordering practices.

“We’re helping to train restaurant managers with their ordering process as well as their inventory management. We’re helping to lay out the back of restaurants from a capacity standpoint. It helps to optimise the capacity efficiency, manage stock rotations and prepare for product deliveries. By doing so, we’re reducing waste and increasing efficiency,“ Clarke says.

Setting themselves apart

As technology has improved efficiency in logistics, Martin Brower still strives to differentiate themselves through service offerings and working intimately with its key customers, Clarke explains.

“We partner with our customer, whether it would be McDonald’s or anybody else, and want to make sure we are offering real value. Our services are by no means the cheapest; we are focussed on ensuring we deliver great value to our customer and through solid partnerships, we support their goals and objectives also.

I think when I look at other business I’ve experienced both in Canada and here in Australia, they tend to be focused on the transaction. Martin Brower looks at a host of value added services that support the restaurant network and corporate goals” he says.

As a global organisation, they are leveraging all those learnings across their entire network of operations. Rather than trying to reinvent the wheel, they are able to provide a level of expertise and support through very unique situations.

How do you market yourself?

Although it does not do a lot of outreach marketing, other quick service restaurants outside of McDonald’s certainly know who they are through their standing in the industry. Expansion plans with other food service providers are always a possibility and something which Clarke says they are looking into with fervour and excitement.

Committed to Developing Talent

Although not a household name, the company’s credibility with all the organisations it works with has increased. Clarke says it is the people that perform all the routine work who make the company what it is. Their commitment to investing in training and developing their employees has taken the company to new levels.

“Opportunities for our people to develop and work on new and exciting projects are something that we as an organisation orchestrate and celebrate. Advancing people and providing them with local and global opportunities is critical to our future success. One of our leverage points for our customer is our ability to bring expert knowledge and support to all our markets” Clarke says.

Common Challenges

Reacting to commodity cost pressures, being more efficient through innovation and providing greater customer value are some of the biggest challenges Martin Brower faces. Clarke explains that some of the other big challenges involve more than one aspect.

“We are committed to making technology work for us by introducing robotics and we will continue to drive innovation in those areas. We’re committed to sustainable operations and our goal is zero waste to landfill. How to offset costs and continue to provide value to our customer is how we continue to evolve the business.

We use wind deflecting materials in our trailers and biodiesel in some of our fleet. Biodiesel is manufactured by converting used cooking oil which comes from the restaurants.

These are just some of the examples of how we can be good partners to our environment and communities in which we operate. It’s a win-win all around.”

Moving forward, Martin Brower strives to continue to deliver superior service for its customers and develop their talented staff to meet the needs of the future.

As Clarke says “We’re very proud of the people who work for us and what we do. We’ve become very good at being efficient and leveraging our expertise.”

AT A GLANCE

WHO: Martin Brower

WHAT: Martin Brower is dedicated to being the leading logistic service provider for restaurant chains around the world, creating an outstanding work environment.

WHERE: NSW 2148

WEBSITE: http://martinbrower.com/

Supporting Partners & Preferred Vendor

Sponsored Advertorial

- FTE

This information will never be shared to third parties

This information will never be shared to third parties