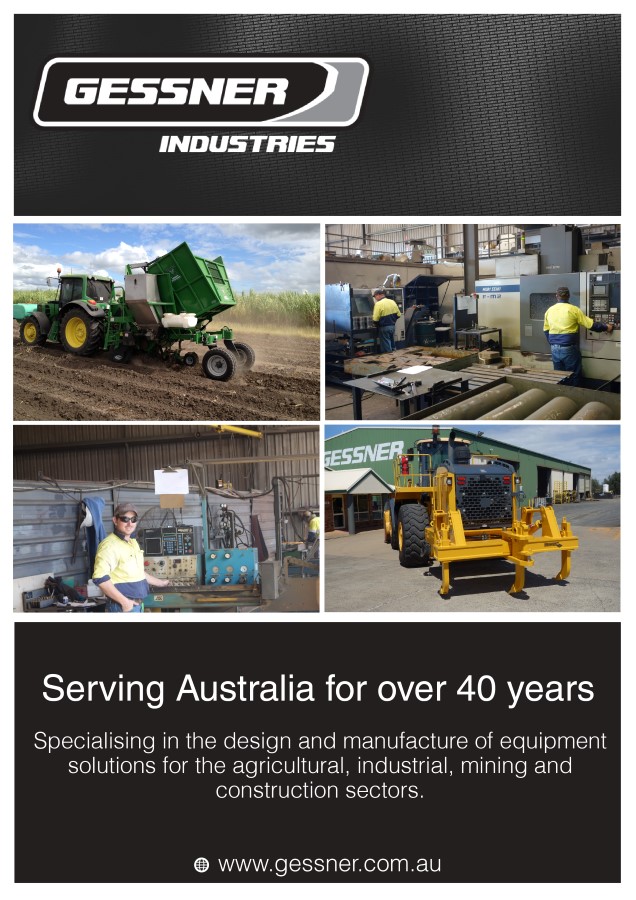

Gessner Industries is one of the most trusted and well-respected names in the design and manufacture of equipment for the agricultural, industrial, mining, and construction industries throughout Australia. The company was founded by Noel and Lindsay Gessner more than 40 years ago and it has since expanded into an industry leader known for the quality of its products as well as the outstanding customer service it delivers to the clients.

In July 2013, Michael and Jim O’Connor purchased Gessner Industries with the aim of further expanding the company’s work and improving its existing services. The two brothers, along with the other members of the board, offered their expertise in combination with the experience of the Gessner Industries personnel in order to transcend the services offered by the company. The new ownership acknowledged the industry experience of the staff and respected their expertise from the very start.

A respected name

When we spoke with Michael O’Connor, he explained to us that the products of Gessner Industries have been highly regarded in its fields of involvement. The equipment provided by Gessner was very high in quality but also priced at a premium which meant that only a certain percentage of the market could actually afford to get their hands on it. After the acquisition, Gessner attempted to find a solution so that it could provide its equipment to additional clients who were unable of meeting the previous price requirements.

Soon after, a decision was made. Instead of selling the equipment through third-party vendors, Gessner would deal directly with consumers. Eliminating the middle party also meant that the costs associated with it could be reduced to a bare minimum. After all, Michael explained that their clients often need to contact the company directly in order to get a better understanding of the intricacies of the equipment and the way that it operates.

Customer service at a direct level

“We adopt a slightly different strategy at Gessner. When we took over the business, it was being ran through a whole series of dealerships around Australia. We very quickly made the decision that Gessner Industries would manufacture and sell directly to the end user and we would continue to have the relationship that we had with previous dealers as they would sell all of our spare parts. So with every machine that sells, there’s always a large quantity of wear and consumable parts that are required. Therefore, we felt we needed control over the full process of selling”, Michael explains.

As such, the spare parts supplied by the company is a crucial part of its business. Gessner is able to supply any necessary items directly to the consumer in a matter of 12 to 24 hours. When a farmer’s equipment needs an extra part, for instance, it is vital that they get it as soon as possible. Since the company is able to provide that service, it offers an additional incentive for prospective buyers of their equipment. They know that their machines will always be fully operational when needed which is extremely important in these industries.

Personalizing equipment for their clients’ needs

This approach has been a crucial part of Gessner. The majority of the equipment manufactured by Gessner is standardized, meaning that it all fits certain criteria. However, each client has specific needs and wants. For example, every farm is different and farmers often need specialized equipment in order to perform their work at the top level. Gessner is not only aware of that but it also specializes in procuring customized parts and attachments that fulfill a client’s requirements.

Any client interested in customized equipment contacts Gessner directly. After a discussion with the appropriate staff, the client agrees on a budget and associated costs. Following that, the client and the company’s designers work on drafts that attempt to provide feasible solutions to the presented problems. Once a full agreement has been reached, the customized equipment proceeds to the manufacturing process as well.

Even after a sale has been completed, Gessner maintains a working relationship with their clients. The industries that the company supplies equipment for are highly active and there is a constant need for proper maintenance. Though the high quality of the equipment means that they are always in prime working condition, some parts still need replacement every now and then due to the nature of the work that they perform.

According to Michael, customizing orders is hugely important for Gessner. In fact, it is one of the many reasons why the company has an advantage over competitors who import their equipment, particularly in the farming sector. Each farm and each region is unique. The farmers know their land and their work better than anyone and they need customized, specialized equipment in order to get the best results possible.

“This is where we have some benefit over the imported equipment of competitors. We do have a reasonable number of Brazilian, U.S., and Canadian competitor products which are, in essence, standardized. I am talking mainly about broadacre planting and cultivation equipment and not everything fits the farmers’ requirements. They have special planting adjustments and other specific farming requirements and needs. There are very few farmers who’ll just walk in and say “I’ll get that”, they generally would like to put their own little strand of what they need to make their farm work”, Michael says.

Constantly expanding and improving

Gessner Industries understands that there is a constant need for improvement, particularly in new equipment. This is not just true for Australia but also for other regions of the world as the company’s equipment finds its way in numerous countries across multiple continents. Recognizing trends in the industry and then reacting appropriately is, after all, a key part of the business which has allowed Gessner to stay on top.

“We have released in the last two years, and still improving on it, a new single row billet planter for the sugar can industry and that has received increased sales outside of Australia. In fact, all of our sugar cane equipment is well received in most of the major growing areas like South America, Southeast Asia, Africa, and Central America. We supply equipment to individuals and though we don’t have dealers at this point in time around the world, we have a reasonable number of individuals or companies that buy our equipment and get it shipped everywhere from Kazakhstan to Zambia. We are also in the process of building a new planter for the market that will be released in August this year”, says Michael.

Safety is a top priority

Of course, none of this would be possible without the company’s staff, the people who are responsible for every part of the process. Gessner is extremely proud of its personnel and Michael explained that the selection process is rigorous. Every single member of the team is there for a reason. The safety of the staff has also been hugely important for the company. This philosophy originated with the founders of the company who put safety at the forefront of their business. After the acquisition, Michael and his brother retained this approach.

“Safety can make or break a business like ours at the end of the day. If people don’t have the right attitude and don’t take safety seriously, you very quickly have a business that can dismantle itself because the attitude and culture is not right. We don’t employ people easily, it’s very hard to get a job at Gessner. It takes weeks if not months at time to get the right people to come into our organization. The new individuals have to fit right in and have the right attitude”, suggests Michael.

Growing the business

As for the future, Gessner are now looking to expand upon their traditional range of agricultural and industrial products. This will include excavator and wheel loader attachments on the industrial arm and new and improved models in both row crop and broad acre agricultural equipment. Michael and his brother Jim have significant experience in the steel fabrication industry, more specifically in the manufacturing of agricultural products. This experience, combined with the wealth of knowledge from the existing Gessner staff, will surely lead to successful results in the future.

AT A GLANCE

WHO: Gessner Industries

WHAT: Designing and manufacturing equipment for the agricultural, industrial, mining, and construction sectors.

WHERE: 20 Molloy Street Toowoomba Queensland 4350 Australia

WEBSITE: http://www.gessner.com.au/

This information will never be shared to third parties

This information will never be shared to third parties